TESCA Services

DESIGN

TEST

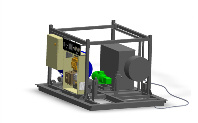

Our consultants have amassed a wealth of experience developing products from initial concept ideas to working prototypes and into to production. As part of this process we are able to produce technical files and using our risk analysis programs conform to health band safety requirements.

This approach encompases the design of small components and nassemblies to large and complex capital equipment. machine or an entirely new product in its own right, we ensure that the design fits the required specifications.

By employing the latest 3D design software we are able to produce 3D printed prototypes at short notice.

We also use the latest in 5 axis machining together with CNC wire erosion to produce prototypes for testing and evaluation prior to commencing full scale production.

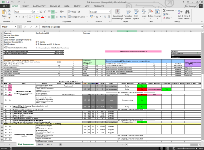

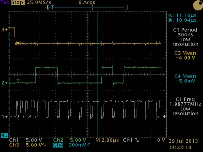

TESCA has undertaken responsiblity for provision of test and validation programs for both large and small maufacturing organisations.

We specialise in the following:

- Electromagnetic compatibility (EMC) Directive.

- Compatability trials.

- Pressure Directive.

- Low Voltage Directive.

- Machinery Directive.

- Environmental testing.

- Risk Analysis

- Fault and failure diagnosis.

- Tribology.

- Software proof evaluation.

Qualification testing is essential before going to market with a new product.

EVALUATE

TRAIN

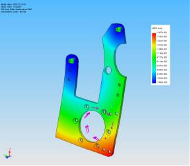

Our consultants have provided businesses of all sizes with advice and analysis on a wide range of industry topics.

These evaluations provide formative information at all stages of the conception, design and production process.

We provide evaluations on:

- Finite element analysis (FEA).

- Metrology.

- Material investigation and selection.

- Process analysis.

- Risk Assessments.

- Mechanical simulation.

- Communication problems between design, production and management within an organisation.

- Equipment survey capability.

These processes have successfully provided significant cost savings to small production organisations and multinational companies.

The Training of operating and maintainence staff is essential in order to ensure that maximum value is obtained from capital investments.

We provide companies with:

- Technical publications and manuals.

- Operator training; to include theory and practical demonstrations.

- Equipment whole life management.

- Maintainence training; to include theory and practical demonstrations together with fault analysis.

Our consultants have provided training programs for international companies, including BAE Systems, Kraft, B.P., Schlumberger, Air Liquid, BOC Linde and W Lucy.

These programmes can be provided in both a classroom environment and at operating sites.